- Products

- Ready Mixed Concrete

- Concrete Blocks

- Aggregates

- Asphalt Products

- Paving & Walling Products

- KPRO Façades & Mortars

- External Wall Insulation

- Roadsurfacing & Contracting

- Precast

- Materials Recovery & Recycling

- Case Studies

- Brochures

- Technical

- Find a Stockist

- Blog

- Health & Safety

- Sustainability

- Events

Manufacture

Products / Precast / Precast Services / Manufacture

- The Factories

- Purpose built factory

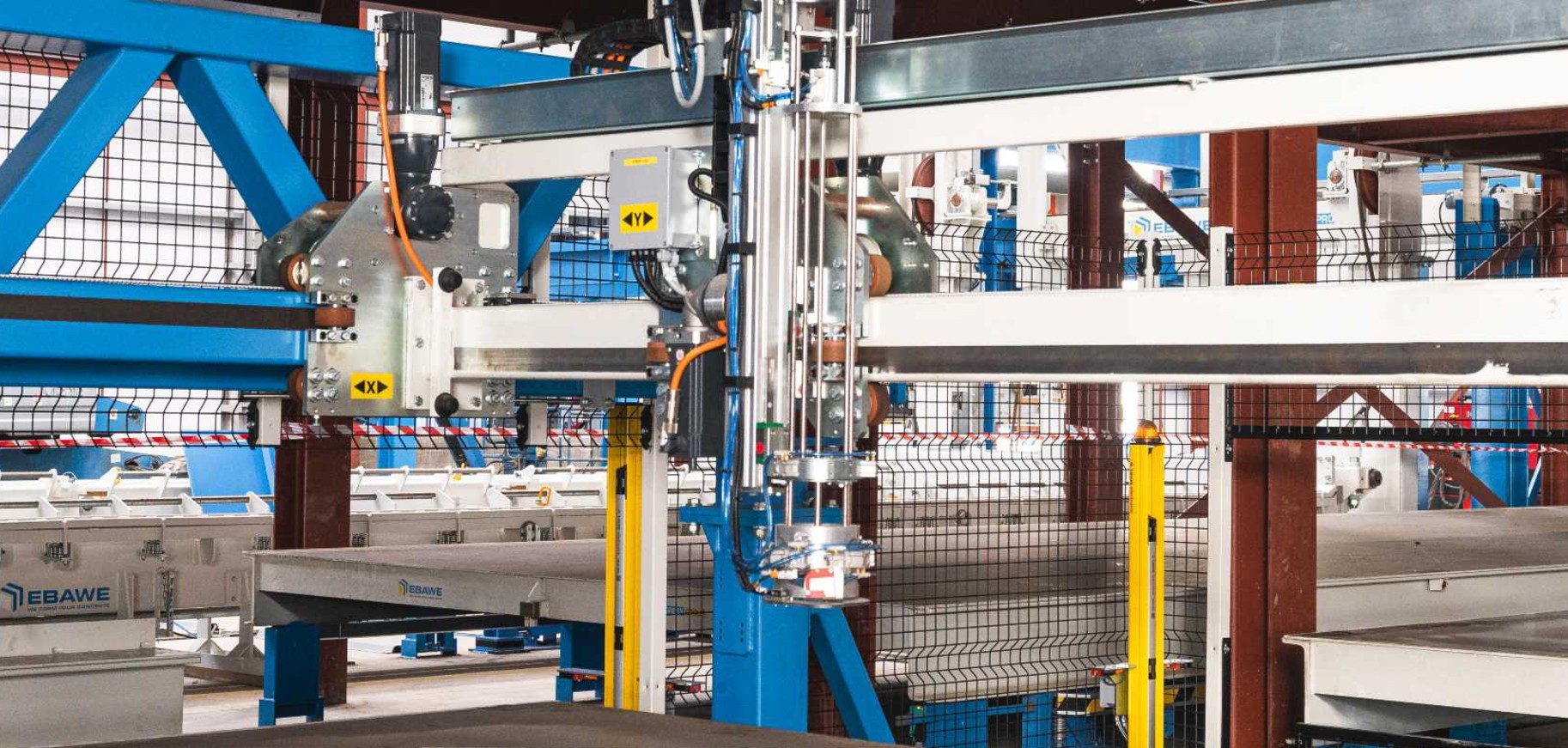

- Fully automated production facility with state of the art carousel plant

- Robots for shuttering, reinforcing and mesh bending & fixing

- 500 m² daily wall production capacity

- Just-in-time technology

- EBOS integrated software

- Detailed production planning

- CAD interface for importing data

- Universal PXML file format

Oranmore, County Galway

- Purpose built facility, extending over 40 acres

- Number of specialist production units for our various products

- Units serviced by on-site steel fabrication and reinforcement bending workshop, along with two concrete batching plants

- Ensures our Quality Control team can monitor all aspects of production process to ensure that the highest standards are maintained

Structural Concrete Manufacturing

- Crosswall: Cellular buildings with many walls such as apartments, townhouse blocks and hotels.

- Spinewall: Open plan buildings with few internal columns, but enough walls to provide vertical structure.

- Flat Slab: Open plan buildings with a significant number of internal columns and few walls.

Production units

Twinwall and Lattice Flooring

Twinwall and Lattice flooring are made in a fully automated carousel production plant. On a single shift rotation, it has a production capacity of 3,500m2 per week. The plant can operate in a double shift pattern to increase capacity as required.

The full production cycle for twinwall takes approximately 48 hours. Beginning at a cleaning station, where the production table is cleaned and polished, the table passes through a series of workstations before reaching a curing chamber. These include a plotting station, where a robotic arm plots the panel outline from the production cad drawing, and a reinforcement station, where the reinforcement is cut and positioned robotically. Due to the highly automated nature of the system nonstandard panel shapes can easily be accommodated.

Prestressed Floor

The prestressed slabs are manufactured in 2 indoor production units, each containing 5 beds of up to 150m in length. A range of cross sectional profiles can be manufactured, ranging in height from 150mm to 500mm. All slabs are prestressed using a combination of 9.3mm and 12.5mm strands.

The hollowcore is formed using a slip form process. The reinforcing strands are positioned and tensioned, prior to the concrete being cast into position. A dry mix with zero slump is used in this unit. This ensures that the voids do not collapse while the concrete is still fresh. The slabs are allowed cure until cube tests indicate that they have reached their required transfer strength. They are then cut to length, and transferred to their storage facility.

Beams, Columns, and Stairs

All frame elements including beams, columns, and stair flights are formed in a fully covered 7,500m2 production area. This unit contains approximately 250 linear metres of steel moulds. This includes adjustable moulds for standard beams and columns, stair flights and portal frame roof beams. Non-standard shapes can be accommodated by using timber inserts, or in certain instances by using full timber moulds. Project specific custom steel moulds can be manufactured on site in the adjacent steel workshop.

All of the above members are cast using a high strength (typically 50N) self-compacting concrete. This eliminates the need for vibration of the concrete. It also results in a superior finish as it greatly reduces the risk of trapped air pockets, and associated surface blemishes.

Components from the product range are combined to provide the building solution.

Brochure Library

Download information on our ways of working and details on the products we offer.